Biomass Heating Facility

Signifying Hotchkiss School’s commitment to becoming carbon-neutral, this facility is a living classroom for students that burns sustainably-harvested woodchips to heat the campus. Its undulating green roof blends into its surroundings while standing out as an iconic landmark.

Hotchkiss School

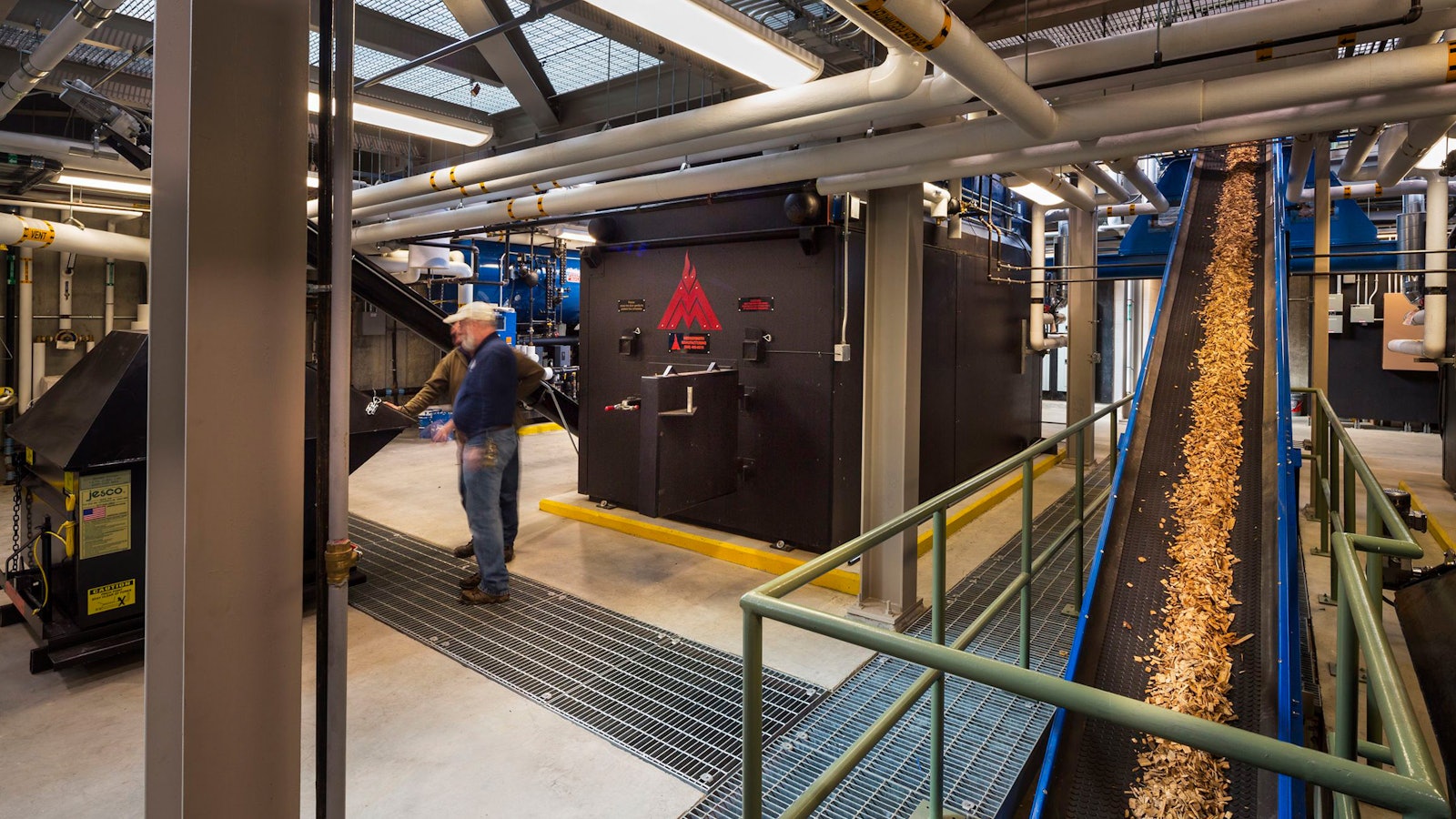

Centerbrook designed this Central Heating Facility to heat all 1.2 million square feet of the 85 buildings that comprise the campus. It burns woodchips and replaces an oil-fired boiler plant, reducing greenhouse gas emissions by a third to nearly a half. The building houses two biomass boilers. Four truck bays feed wood chips into a 17,500-cubic-foot storage bin capable of supplying a week’s worth of fuel.

The facility was designed to do three incongruous things at once:

- It was to be, foremost, an iconic landmark signifying the school’s commitment to becoming a carbon-neutral campus by 2020.

- It was also meant to gently merge with the landscape in a genial display of ecological principles.

- It was to be not only a heat plant, but also a classroom for the advancement of ecological awareness.

Two Messersmith boilers operate at 80 percent efficiency and generate 20 million BTUs per hour burning waste wood acquired from sustainably harvested local forests certified by the Forest Stewardship Council. The woodchips replace 150,000 gallons of fuel oil per year and cut emissions overall, most dramatically sulfur dioxide, by more than 90 percent. Waste ash from combustion is collected for use as fertilizer for the school’s gardens, and an electrostatic precipitator removes 95 percent of particulate matter from emissions.

Woodchips collected from managed timber stands are considered a “carbon neutral” fuel by the International Panel on Climate Change because the CO2 produced by their use is reabsorbed by the ecosystem through regrowth of the forests where they originate. Biomass heating is expected to reduce Hotchkiss’ carbon footprint by more than 6 million pounds of CO2 a year. There are currently 80 biomass facilities in 20 states.

This facility was one of only three LEED Certified power plants in the country at the time it opened. The vegetated roof combines with a bioswale/rain garden system to absorb rainwater and filter runoff before returning it to the ground.

Tours of students and community groups have access to a mezzanine balcony that overlooks and circumnavigates the boiler room. Wall-mounted displays and a series of interactive computer consoles track performance data. Outside, a nature path (below) passes by the vegetated roof on its way to a rain garden, bioswales and nearby wetland.

“Our goal for this project was to build upon a philosophy that further connects students to the natural resources they use daily ... This building, built as a classroom, prepares them to make creative and intelligent choices in a world with ecological limits.” Josh Hahn, Assistant Head of School and Director of Strategic Initiatives

Centerbrook also designed the LEED Certified and six-time award-winning Esther Eastman Music Center at Hotchkiss.

PRESS & AWARDS

Press

Awards

- Connecticut Treasures Award, AIA Connecticut

- Honor Award, AIA Connecticut

- Honor Award, AIA New England

- American Architecture Award, Chicago Athenaeum’s Museum of Architecture and Design and The European Centre

- Green Building with Wood, Wood Design Awards

- Alexion Award of Excellence, Connecticut Green Building Council

We're using cookies to deliver you the best user experience. Learn More